Vacuum Pump UP28

The UP28 vacuum pump can be triggered on demand to support the brake booster. If the combustion engine does not supply sufficient vacuum under certain operating conditions, i.e. cold start/warming up phase, the UP28 supplies the vacuum to ensure brake booster operation.

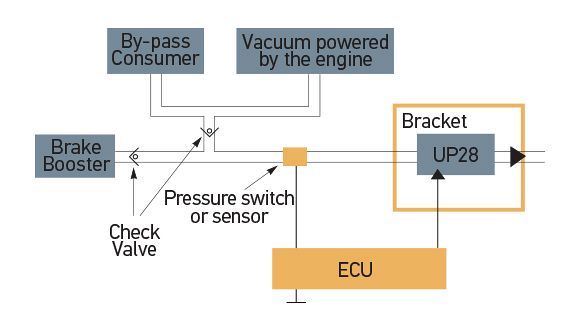

The UP28 is installed parallel to the main combustion engine. The UP28 sucks in filtered air via the brake booster and flexible pipes. To enable accurate pressure measurement by the control unit, non-return pressure valves are installed (see diagram). The electric contact between the UP28 and the control unit is established via a cable equipped with an engine compartment plug attached to the vacuum pump.

The braking system is one of the most important systems in any vehicle. To ensure that a constant and effect brake power is accessible at all times, the use of a vacuum pump is often necessary. Most vehicle brake boosters use a vacuum that is generated by the naturally aspirated engine. Current engine development projects mainly aim to increase the efficiency of drive concepts and further conserve resources. Substantially lower fuel consumption can be achieved by e.g. running the engine as unthrottled as possible, which under certain operating conditions, may result in an insufficient vacuum supply from the combustion engine for brake boost.

Rollover/tap the icons below for further details:

Specifications

Operating Temperature Range |

– 40 °C … + 100 °C (< 20 min. up to + 120 °C) |

Voltage |

10.5 - 16V DC |

Maximum Vacuum Level |

≥ 86 % (below ambient pressure level) |

Pressure build-up time at 100 hPa ambient pressure, 12V |

pabs = 500 mbar in t ≤ 6 sec |

Test Volume |

Approx. 3.2 l |

Pump Operating Time |

> 600 hours |

Switching Operations |

> 450,000 |

Notes |

Red wire = Positive |

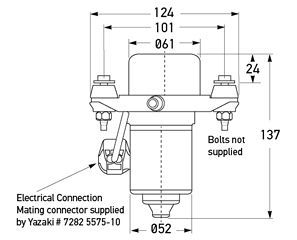

Outline